Comet 30 Series

Torque Converters

Comet 30 Series Clutch Catalog. Genuine Comet 30 Series Torque Converter Parts for 3 to 8hp Go Karts and Mini Bikes. Comet CVT Parts. Comet 30 Series Driver Clutches, 30 Series Driven Pulleys and individual Comet 30 Series Parts. These Asymmetric Components use a Belt that's flat on one side and angled on the other. By having both the clutch and the driven pulley fixed sheave faces on the same side, the system can be mounted on a fixed plate, in the same plane. Comet Industries USA. We also carry imported copies. The Modern Comet Components are Black. The Imported Components are Silver. The Early Comet Components, Manufactured Prior to 2009, were also Silver.

|

Genuine Comet 30

Series Driver Clutches

|

|

DRIVER CLUTCH 3/4" 30S |

69.50 |

|

|

DRIVER CLUTCH 1" BORE |

79.50 |

|

American Comet 30 Series Clutches. Genuine Comet 30 Series Clutches are available in 3/4" Bore or 1" Bore, and use an Asymmetric, 3/4" Top Width Belt. Mounting Bolt and Washer included. 4-19/32" Outer Diameter. The Clutch Bolts Firmly to the Engine Crankshaft, and Must Not Float. Engages at approx 2200 RPM - Max. 3100 RPM. Comet 219552A is the Most Popular Torque Converter Clutch in the United States. Made in the USA. |

|

|

Genuine Comet 30

Series Driven Pulleys

|

|

DRIVEN 5/8" 30S 6" |

69.50 |

|

|

DRIVEN 3/4" 30S 6" |

69.50 |

|

|

DRIVEN 5/8" 30S 7" |

69.50 |

|

|

DRIVEN 3/4" 30S 7" |

69.50 |

|

American Comet 30 Series Driven Pulleys with Snap-in Buttons are available in 5/8" Bore and 3/4" Bore, with a Choice of 6" or 7" Outer Diameter. The Comet 30 Series Torque Converters use an Asymmetric, 3/4" Top Width Belt. Has a Green Tension Spring and Six Black Snap-in Buttons. Mounts OUTBOARD, with the Tension Spring Facing Away from the Engine. |

|

|

Genuine Comet 30

Series 16mm Pulley

|

|

COMET 30 SERIES 16MM PULLEY |

74.50 |

|

The First American Comet 30 Series 16mm Torque Converter Pulley, Ever. Genuine Comet 16mm Driven Pulley x 6" Outer Diameter. American Upgrade and Replacement for the Imported Chinese 16mm Pulleys on American Sportworks Go Karts, Trailmaster Go Karts, Hammerhead Go Karts, Coleman and many other brands. Fits on a 16mm "Step Down" Jackshaft. A Step Down Jackshaft is 16mm and steps down to 14mm. Replaces the 16mm Asymmetric 30 Series Style Chinese Clones that use a 3/4" Top Width Belt, that's Flat on the Engine Side. Mounts OUTBOARD, with the Tension Spring Facing Away from the Engine. Made in the USA. |

|

Models with Comet 30

Series Torque Converters

Manco Go Karts with Tecumseh Engines or Robin Subaru Engines ("L" shaped Foot Pedals w/3 Holes). Manco Dingo Go Kart Model 285 and 286. Manco Fox Go Kart Model 485, 486, 606 and 806. Manco 6hp Big Cat Mini Bikes with Tecumseh Engines and Huge ATV Wheels. Manco Driver Clutch Part #5957. Coleman Go Karts and Mini Bikes, Masters of Motion Go Karts with Tecumseh Engines (Fort Wayne, IN). Murray Go Karts with Tecumseh Engines, Murray Driver Part #680167 and #1201404. Kartco and Road Boss Go Karts with Tecumseh Engines (Made in Mississippi). Avenger Yellow Jacket Go Karts with Tecumseh Engines (Made in Louisiana). Carter Brothers Go Karts with Asymmetric Torque Converters and Tecumseh Engines. Hammerhead Mudhead Driver Clutch Part #9.500.010 and Driven Pulley #9.500.001. Hammerhead 80T Driver Clutch Part #9.500.010 and Driven Pulley #9.500.001. Brister's ThunderKart Go Karts with Tecumseh Engines (Made in Louisiana in the 90's). 200cc Trailmaster Mid XRX Go Karts, Klipper Go Karts, ProKart Go Karts, Ken Bar Pathwinder Go Karts and Streaker Go Karts under 8 horsepower, Tecumseh Engines. Trailsport Buffalo Mini Bikes with bolt on, Comet Torq-A-Verter Kits (TAV2). BKS (Bob's Kart Shop) Groundhawg LX and BKS Kangaroo LX Go Karts. Yerf-Dog Go Karts with Tecumseh Engines, Yerf Dog Go Kart Model #1400, 3002, 3200, 3202, 3203, 3203A, 3205, 30021, 30034A, 32001, 33002 and 33200.

The Black and Silver Components on

this page are compatible and can be mixed.

|

Imported Clutches

|

|

1" BORE CLUTCH - 30S |

19.50 |

|

|

3/4" BORE CLUTCH 30S |

29.50 |

|

Uses a 3/4" Top Width Asymmetric Belt. |

|

|

Imported

Driven Pulleys

|

|

DRIVEN 5/8" BORE 6" |

39.50 |

|

|

DRIVEN 16MM BORE 6" |

39.50 |

|

|

DRIVEN 5/8" BORE 7" |

39.50 |

|

Choice of 6" or 7" Outer Diameter.

|

|

General Information

Engages at 2200 RPM - Max 3100 RPM

How does a torque converter work? The drive clutch is activated by centrifugal force from the engine crankshaft. The moveable sheave of the clutch is forced in as the RPM of the engine is increased. This contacts the drive belt. The drive belt will then be forced to a larger diameter within the clutch sheaves, thus pulling it to a smaller diameter within the driven unit sheaves. The moveable sheave of the driven unit is forced out, allowing the belt to seek it's smaller, high speed ratio diameter. As this happens, the speed from the engine transferred to the final drive is increased.

The asymmetric torque converter components use a 3/4" top width belt. The belt mass is desirable in applications requiring extra rugged driving ability, such as dune buggies, go karts, mini bikes, ATV's, grounds maintenance equipment, materials handling devices and industrial equipment. It's mounted with both stationary sheaves inboard requiring only minimum displacement. All the working parts are on one side.

The asymmetric type torque converter system has sheave faces that have different angles. It uses a belt that's flat on one side and angled on the other. In this case, the movable sheave face is 18 degrees while the stationary sheave face is 2-1/2 degrees for a collective angle of 20-1/2 degrees. By having both the driver clutch and driven pulley fixed sheave faces on the same side (inboard) the system can be mounted on a fixed plate, in the same plane. See the 30 Series TAV2 Complete Kits. This offers some very significant advantages to mounting requirements in many cases. Noting the displacement diagrams you will see that the torque sensing cam assembly is mounted outboard adding further to the convenience of many installations with displacement problems. The asymmetric concept, having the 18 degree angle on one side requires less sheave face travel to lift the belt to larger, comparable pitch diameters of the symmetrical system. This makes it possible to force the belt to a diameter within the drive clutch (at high RPM) that exceeds the usual 1:1 ratio of standard systems. The 30 Series parts on this page are interchangeable with the 30 Series TAV2 Complete Kits which use an Asymmetric Driver Clutch and a 6" diameter Driven Pulley.

The spring and flyweight assembly in the driver clutch actuates the movable sheave and responds to engine RPM and should be replaced if the pins or springs are even slightly loose. If they are not VERY tight the loose pins and springs will prevent the pulley from disengaging. If your machine tries to take off by itself you may need to replace this part. Other problems that could be causing the system to be engaged all the time: dirty components with a lack of lubrication, worn out splined hub, the drum not correctly installed or a weak spring in the driven pulley.

1" Bore Clutches don't use a Bronze Bushing.

|

Outer Drum for

3/4" Bore Clutch

|

|

OUTSIDE DRUM 3/4 DRIVER |

15.50 |

|

Genuine Comet Outside Drum |

|

|

TC Clutch Bolt Kit

5/16-24 and 3/8-24 Bolts

|

G30140 |

TC BOLT KIT 3/8,5/16 |

4.20 |

|

Torque Converter Clutch Bolt and Washer Kit. The Kit includes one Clutch Cover Washer, one 5/16"-24 Bolt and Split Lock Washer and one 3/8"-24 Bolt and Split Lock Washer. This is the Bolt that screws into the end of the Engine Crankshaft to hold the clutch on. |

|

|

Stock Spring and

Flyweight Assembly

|

|

SPRING AND FLYWEIGHT |

24.50 |

|

|

SPRING FLYWEIGHT ASSY |

14.50 |

|

Spring and Flyweight Assembly for Comet 20 Series and 30 Series Torque Converter Driver Clutches. If this part goes bad, the clutch stays engaged all the time. Part #200344A is a Genuine Comet Part, Made in the USA. Part #115592 is Made in China. |

|

|

Comet Speed Limiter

Comet Speed Reducer

|

|

COMET SPEED LIMITER |

38.50 |

|

Genuine Comet Speed Limiter for Comet 20 Series and Comet 30 Series Torque Converters. The Comet Speed Limiter is the answer to control speed when inexperienced drivers get behind the wheel. Reduces speed by up to 50%, down to as low as 12 to 15 miles per hour. Comet Industries USA. |

|

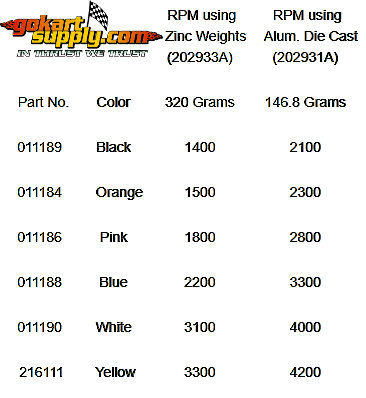

Spring Engagement Chart

|

Comet Garter Springs

|

|

ORANGE SPRINGS |

14.50 |

|

|

PINK SPRINGS |

14.50 |

|

|

BLUE SPRINGS |

14.50 |

|

|

BLACK CLUTCH SPRINGS |

14.50 |

|

|

WHITE SPRINGS |

14.50 |

|

Set of 2 Genuine Comet Garter Springs

For Comet 20 and 30 Series Torque Converters. |

|

|

Comet Flyweights

|

|

ALUMINUM WEIGHTS |

29.50 |

|

|

ZINC WEIGHTS 320G |

29.50 |

|

Genuine Comet Weights

Spring Sets sold separately.

|

|

|

Splined Moveable Face

Genuine Comet 219205A

|

|

MOVABLE FACE 3/4" BORE |

22.50 |

|

Genuine Comet 219205A Splined Moveable Face for 3/4" Bore Comet 30 Series Driver Clutch. |

|

|

Comet Splined

Hub for 3/4" Clutch

|

|

SPLINED HUB FOR 3/4 DRIVER |

14.50 |

|

Genuine Comet 200376A Hub |

|

|

Splined Hub for 1"

Bore Clutch 1/4" key

|

|

HUB FOR 1" BORE 1/4 KEY |

34.50 |

|

Genuine Comet 203641A Hub |

|

|

Fixed Sheave

for Driver Clutch

|

|

FIXED SHEAVE, STATIONARY |

23.09 |

|

Fixed Stationary Sheave for Asymmetric Comet 30 Series Torque Converter Clutches and Asymmetric Chinese Clones. American Sportworks 14698 - American Landmaster 14698 (Clutch Group) |

|

|

Bronze Bushing for

3/4" Driver Clutch

|

|

BRONZE BUSHING |

6.50 |

|

|

BRONZE BUSHING |

4.00 |

|

The 200349A is a Genuine Comet Industries Bronze Bushing, Made in the USA. The 115593 Clutch Bushing is Imported. The belt rides on this bushing. For 3/4" bore clutch only. The 1" bore clutches do not use a bronze bushing. |

|

|

Genuine Comet

Driven Pulley Snap Ring

|

|

RETAINING RING 20/30S |

7.50 |

|

|

|

Genuine Comet 30

Series Tension Spring

|

|

GREEN SPRING FOR 30 SERIES |

9.50 |

|

Made in the USA.

STOCK Green Driven Pulley Spring.

This Tension Spring Must Be Pre-Loaded.

Read the Spring Installation Instructions Below!

|

|

Tension Spring

Installation Instructions 215699A

Adjusting the spring tension on the driven pulley changes the rpm range at which the unit shifts into high gear. The three numbered holes on the cam are used to change the spring tension. Hole #1 provides the least tension and allows the unit to shift gears at a lower rpm. This is good for flat ground. Hole #3 provides the most tension and allows the unit to shift gears at a higher rpm. This is good for hilly terrain. Hole #2 is the factory setting providing medium tension good for the most common riding conditions.

You must pre-load the spring when installing it into the driven pulley. After placing the end of the spring in the desired hole and aligning the flat spots in the center of the cam with the flats on the post, just before pushing the cam all the way on to the post, turn the movable sheave clockwise -- tightening the spring -- bringing the buttons past the points of the cam and into the next valley. While holding tension on the spring, push the cam all the way on to the post and secure it with the snap ring. When you release the movable sheave the spring should rotate it counter-clockwise until the plastic buttons press against the cam. The insert buttons must not "float" between the cams.

The "20" stamped on the cam indicates that it is a 20 degree cam, not that it is a Series 20 torque converter. The 20 degree cam is used on both the 20 and 30 Series torque converters. One way to tell the two apart is to look at the angle of the pulleys. On the 20 Series, both pulley sheaves have the same angle. On the 30 series, the sheave toward the motor is nearly flat while the opposite sheave is angled.

|

Genuine Comet 204114A

CAT99 Driven Pulley Spring

|

|

RED DRIVEN SPRING CAT 99 |

12.50 |

|

Genuine Comet 204114A CAT 99 Tension Spring. Fits Asymmetric CAT 99 Driven Pulleys that use 3 Insert Buttons and a 5/8" Top Width Belt. CAT99 Torque Converter Pulleys were Manufactured Prior to 1995. The newer Asymmetric, Comet 30 Series Torque Converters, use 6 Insert Buttons, a Green Tension Spring and a 3/4" Top Width Belt. |

|

|

Set of 3 Genuine

Comet GLUE-IN Buttons

|

|

BAG OF 3 INSERT BUTTONS |

6.50 |

|

Set of 3 Genuine Comet GLUE-IN Buttons for the Old Style, Silver Driven Pulleys that use 6 Glue-in Buttons. Fits Comet 20 Series and Comet 30 Series Torque Converters. Glue in place with contact cement or equivalent. Comet 204332A Buttons. Comet Industries- Made in the USA.

|

|

The insert buttons must be in place at all times. Don't run the system if any of the buttons are missing. Missing buttons will allow the driven pulley to open too far, and the belt will go down into an area of the pulley where it's not supposed to go. If the belt comes in contact with the rivets, it usually damages the belt. In addition, the buttons also keep the movable sheave from spinning, they reduce friction between the cam and the movable sheave and they prevent metal to metal contact, acting as shock absorbers so they play an important role.

|

Set of 3 Genuine

Comet SNAP-IN Buttons

|

|

3 SNAP-IN BUTTONS |

7.50 |

|

Set of 3 Genuine Comet SNAP-IN Buttons for the New Black Driven Pulleys that use 6 Snap-in Buttons. Fits Comet 20 Series and Comet 30 Series Torque Converters. Comet 219818A Buttons. Comet Industries - Made in the USA.

|

|

|

Genuine Comet TAV2

Torque Converter Cover

|

|

TAV2 COVER |

36.50 |

|

Comet TAV2 Cover with 4 mounting bolts. Comet 30 Series Torque Converter Cover. Thin, Plastic. Fits Comet TAV2 Kit Part #218352A, 218353A, 218354A and 218355A. Comet Industries USA. |

|

|

Comet TAV1 Cover

|

|

TAV1 COVER |

32.50 |

|

Genuine Comet TAV1 Torque Converter Cover. Fits Comet TAV1 Mounting Plate Part Number 211349A. Use with 6" outer diameter driven pulley only.

|

|

|

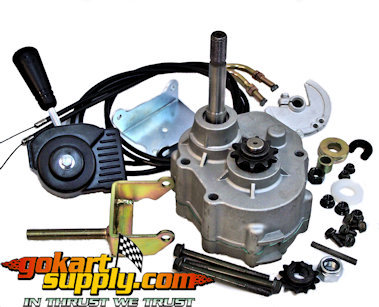

Forward Neutral

Reverse Transmission Kit

|

|

REVERSE KIT |

126.50 |

|

Go Kart Transmission. Go Kart Forward and Reverse Gear Box Transmission Kit for 3hp to 8hp Engines. Fits for Hammerhead and Trailmaster Go Karts with Reverse and many other applications. 16mm Shaft with a 5mm Keyway. 12 Tooth Sprocket for 35 Chain and a 10 Tooth Sprocket for 40, 41 and 420 Chain. Gearbox Positions: Forward, Reverse, Neutral. Forward Gear Ratio: 1:1:3 - Reverse Gear Ratio 1:2:6 ... Kit Includes: The Shifter Control, Shifter Disc, Shifter Cables, (2) Mounting Plates, 10 and 12 Tooth Sprockets, Shifter Assembly, 5mm Key and Hardware. Weight: 9 lbs. |

|

Maintenance

Maintenance will include proper cleaning and lubrication of the Driver Clutch and the Driven Pulley. Inspect the torque converter on a regular basis for dirt, frayed belts and any other potential problem obvious from a visual inspection. Always service units before each season. Maximum service interval recommended is each 50 hours of operation.

The Driver Clutch on the Engine Crankshaft, and the Driven Pulley should be Parallel. Friction Faces must be smooth and free of dirt, corrosion, oil or grease. Belt must be dry, straight, and free of cracks, breaks and uneven wear. Operating the vehicle in a dusty environment will require more frequent servicing.

Use Comet Dry Film Lubricant in all models of Torque Converters.

Indicators of a torque converter system requiring cleaning and lubrication are erratic or jerky engagement upon acceleration and a tendency to apparently "lock" into a particular speed (a second cause of jerky engagement is an excessively loose drive chain). If either one of these conditions exist service the unit immediately. Both driver and driven pulleys should be disassembled and cleaned.

C = Clean - L = Lubricate

Visit the Trouble Shooting Page for more information on malfunctioning Torque Converters. Belts eventually wear over time but a damaged or torn up drive belt always indicates that a problem exists with the system. Only replace your drive belt after the problem has been corrected. Components must be clean, lubricated and perfectly aligned to function properly.

If you own an early model Manco 5 or 6 horsepower go kart powered by an Asymmetric Torque Converter CLICK HERE to view the assembly sequence of your drive system. This is the old style Manco Factory set up that used a thick plastic cover that snaps down over two arms that stick out. The torque converter cover style and cover hardware may vary on later models, but the mounting plate, jackshaft, bearings and components are all the same. If your Manco brand kart is equipped with a 12 tooth jackshaft sprocket, you have #35 chain. If your Manco brand kart has 9 tooth jackshaft sprocket, you have #420 Chain.

How do Asymmetric Torque Converters Work? As the engine R.P.M. increases, the Driver pulley flanges continue to close together. This action, in turn, is squeezing the belt out to a larger diameter. This action is dependent on acceleration and lack of torque load on the Driven element, allowing it's pulley flanges to open thus creating a smaller driven unit diameter. If the torque load is increased this ratio is reversed instantly and smoothly to it's requirement. The ratios between low and high are infinite to meet all demands within it's realm of capabilities.

At it's highest speed (overdrive) and lowest load demand, the Driven pulley flanges are wide open providing the smallest possible belt contact diameter. The Drive unit pulley flanges, at this point, are closed to provide the largest possible belt contact diameter. The unique asymmetric arrangement of the belt and pulley angles allow the belt to exceed diameters possible with the standard "V" pulleys, thus overdrive.

|

M6 Tinnerman Nut

Plastic Belt Cover Nut

|

|

M6 TINNERMAN NUT |

6.75 |

|

Genuine American Sportworks 14892 Tinnerman Nut. M6 Belt Cover Nut. Plated. American Landmaster 14892 / Hammerhead 14892 |

|

Factory Authorized Distributor